Precision Machining

From power generation to transportation, when time, technology or capacity is in short supply, the world’s leading brands count on Concorde Precision Machining.

Our History

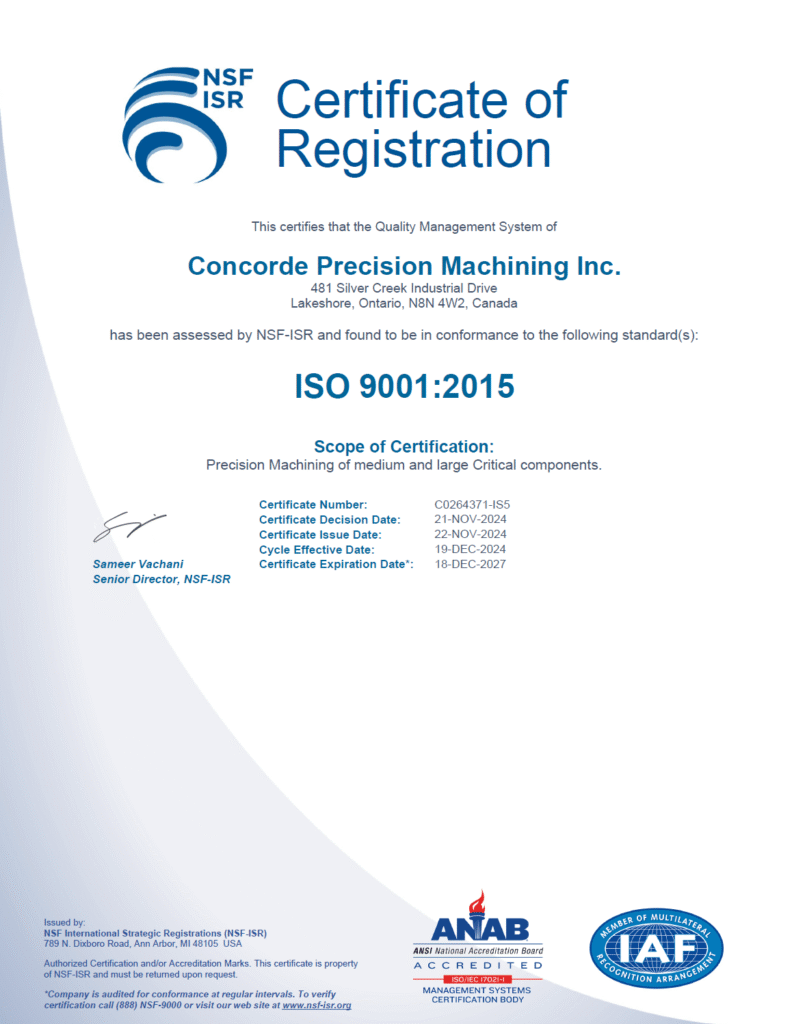

Concorde Precision Machining traces its origins to the expertise of a seasoned machinist renowned for crafting parts for the iconic Concorde supersonic jet. In 1994, the company joined forces with Reko International Group, signaling a new chapter in its legacy. Today, Concorde continues to embrace its heritage of precision and excellence, a testament to the enduring values instilled by its founders.

Our clientele spans various sectors within heavy industry. Operating from cutting-edge facilities boasting 100,000 square feet of machining space, we strategically position ourselves on the Ontario-Michigan border, ensuring seamless access to key manufacturing hubs across Canada and the U.S.

Integral to our identity is the cohesive bond among our team of skilled tradespeople. With a focus on nurturing longstanding relationships, we take pride in serving both legacy and new clients alike. This collective dedication forms the cornerstone of Concorde’s past, present, and future success.

Our Core Business

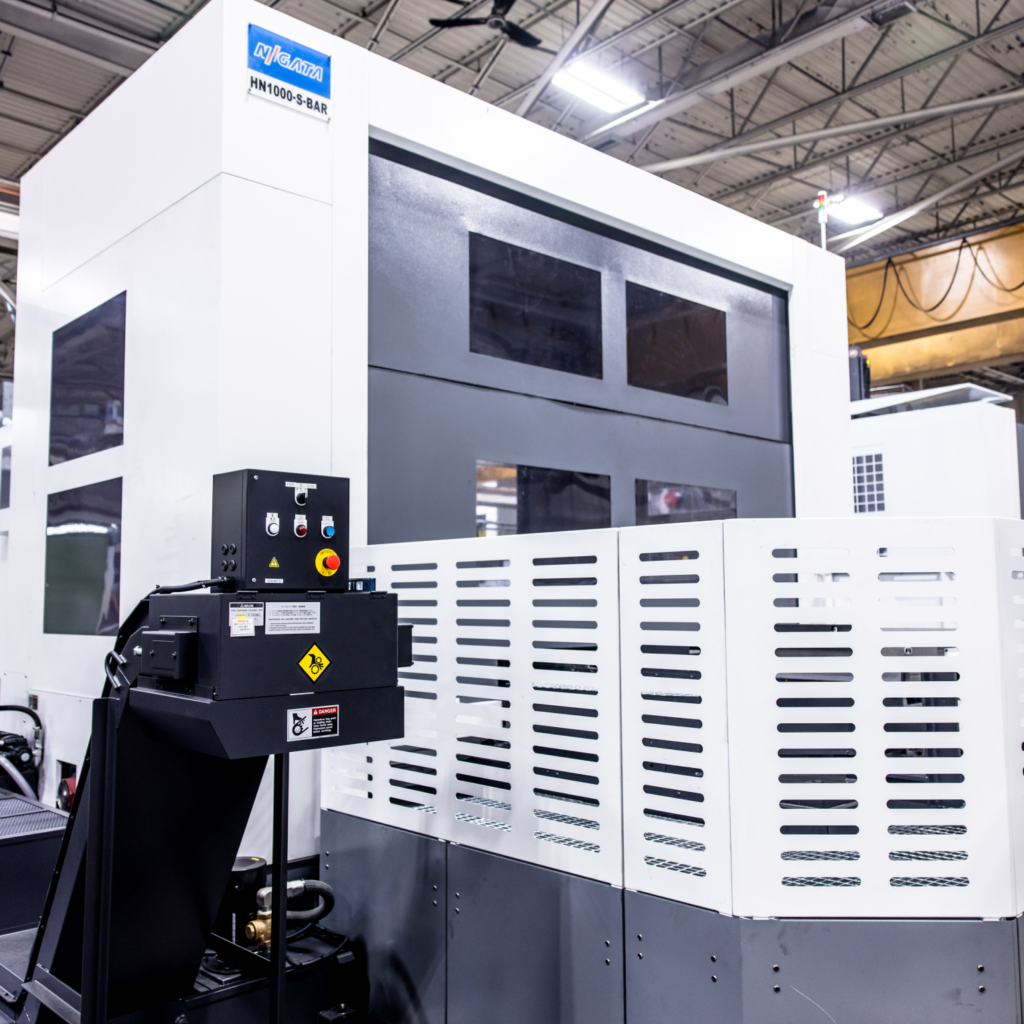

Critical Component Machining

From casting to forging and fabricating to milling and boring to engines and their components, Concorde’s diverse capabilities can alleviate supply chain problems and provide assembly-ready machined components up to 100,000 pounds. That includes but is not limited to:

Oil & Gas

Connecting rods, cross-head guides, engines, flywheels, fluid ends, gearboxes, pressure cylinders, mud pumps, power heads, suction and discharge modules and compressor frames.

Rail And Marine

Cast and fabricated engines, frames, engine covers, tappet covers, cylinder heads and generator housings.

Mining

Vehicle bodies, crawlers, gear racks, hubs, lift beams, ranging arms, transfer cases, axle housings and carrier arms.

Energy

Nuclear transfer carts and platforms, skid plates, stators, turbine casings and riser plates.

Power Generation

Cast and fabricated engines, frames, engine covers, generator housings, and cylinder heads.

Value Added Services

Our primary focus is critical component machining, but we also offer secondary services to help customers streamline their vendor management.

Those include CMM inspections, parts washing, clean room validation, subassembly services and remanufacturing. All to streamline our customers’ manufacturing processes, save money and alleviate environmental stress.

Joining Concorde

At Concorde Precision Machining, we are always looking to attract the most talented individuals to join our team.

Our No. 1 goal is to build a bright future – for employees, the company, and the wider world. New hires can expect a healthy work-life balance, competitive wages, benefits, a company-matched retirement savings plan, referral bonuses, opportunities for personal and professional growth, corporate discount programs, and more.

Importantly, from Day 1, employees can trust they’ll receive top-notch training and be treated with the respect and recognition they deserve for a job well done.