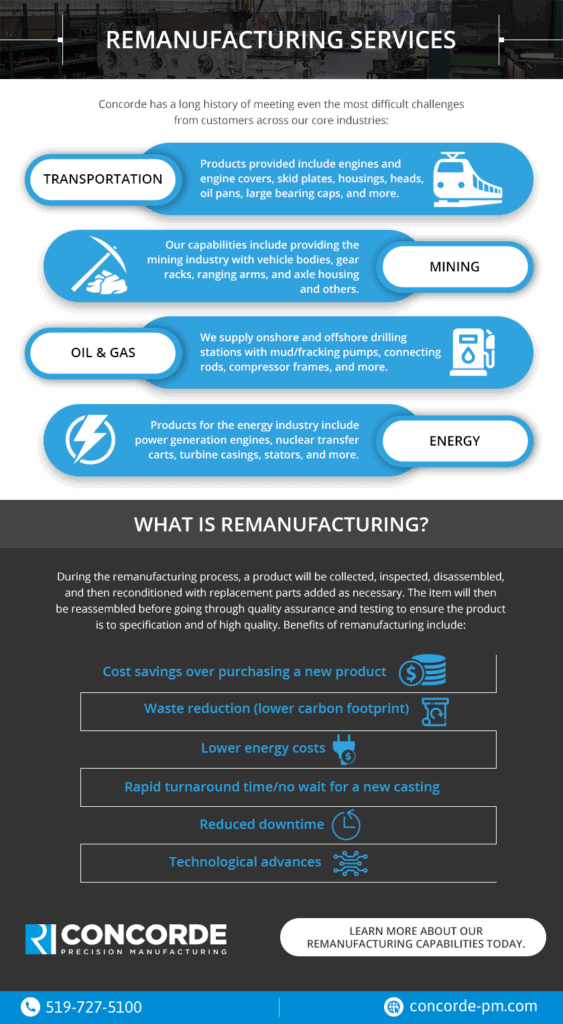

Remanufacturing is the process of taking a previously used product or part and restoring it to a like-new condition. Remanufacturing services create items that are equal to a new product in every aspect. The advantages of these newly remanufactured components are that customers can purchase them for a reduced price compared to a new one.

At Concorde Precision Machining, our goal is providing customer satisfaction through quality components. Our expertise in precision machining and industrial remanufacturing has enabled us to maintain an ISO 9001:2015 certified facility. Some examples of our remanufacturing services include:

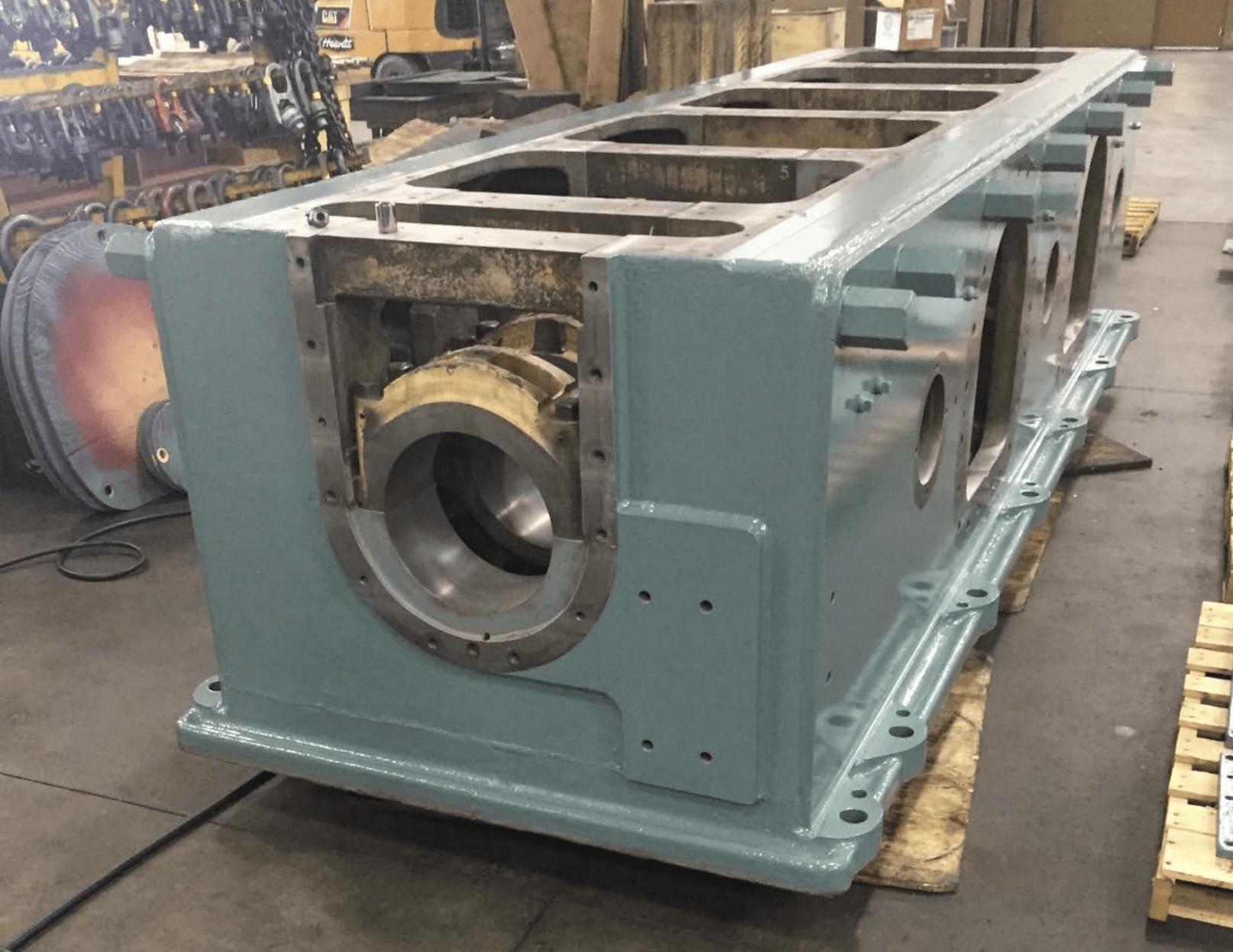

- Cut-down and re-bore for reciprocal and centrifugal compressors

- Remanufacturing of heavy equipment engines

- Remanufacturing/re-machining of compression components