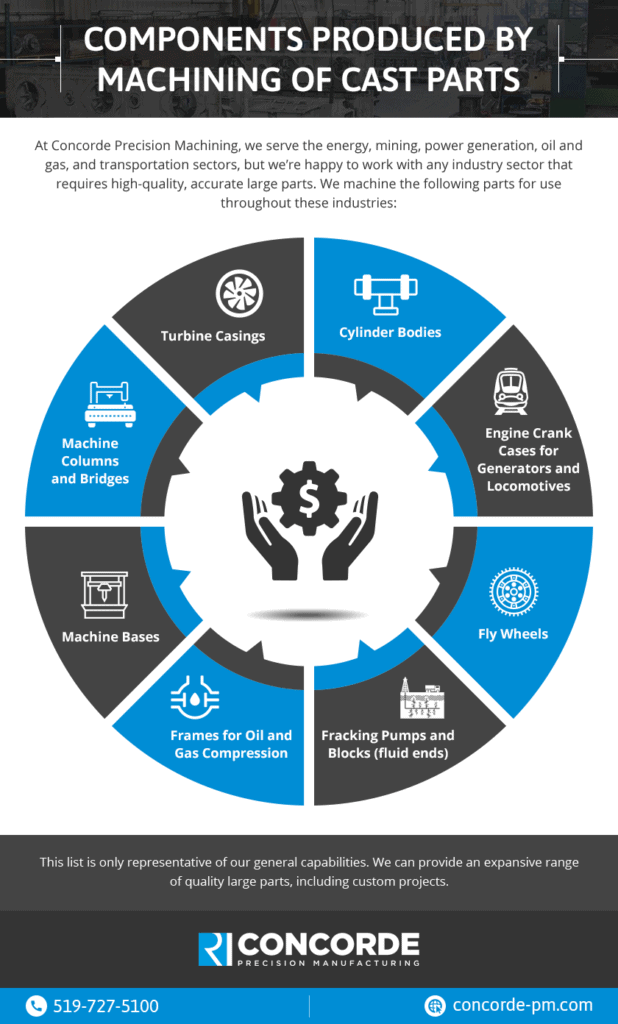

Machining of large cast parts is its own niche in the manufacturing world. At Concorde Precision Machining, we specialize in creating large components for heavy machinery from cast steel and iron through a wide range of large part machining techniques. We serve the needs of demanding industries with our extensive machining capabilities, including 5-axis machining and large diameter boring.

Machining Capabilities

Our in-house machining capabilities are extensive, and we can handle standard and custom part designs. Our capabilities include:

- Contour boring

- Deep hole drilling

- Large 5-axis machining

- Large diameter boring

- Large horizontal and vertical boring

- Large vertical and horizontal machining

Each of our processes is tailored to work with large and oversized parts. These parts need specialized handling to avoid distortions, cracks, and other flaws in the workpieces that can delay production. The team at Concorde Precision Manufacturing knows how to best handle workpieces from rough incoming material to finished product so our customers have high-quality parts they can rely on.