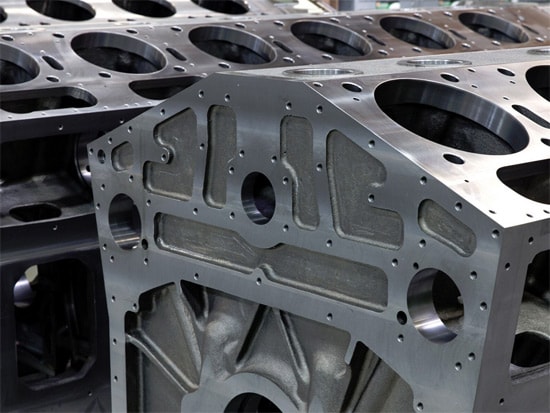

At Concorde Precision Machining, our team members are experts in large diameter CNC milling and boring. We have extensive in-house equipment capabilities and can complete complex parts machining within tight tolerance levels for low- and medium-volume machining projects.

Our machining capabilities include precision horizontal boring and contour boring. We also complete deep hole drilling projects. Our equipment can mill and bore parts of up to 40 feet long for both oversized and large diameter workpieces. We handle large part machining projects for multiple industries that need large machinery and process equipment.

We also provide complete milling services for cast or forged components. Our large CNC machining capabilities guarantee precision and efficiency for small and large production orders.